Many friends who bought Mankate underwater epoxy reinforced adhesive came to ask us. Is this underwater epoxy resin reinforced adhesive different from ordinary epoxy resin reinforced adhesive? Is there any detail in the construction of the glue that needs attention? In view of the fact that many friends are not clear about the construction process of underwater epoxy resin, this article will explain the use of underwater epoxy adhesive and the details that need attention in construction. Let's take a look.

Still complaining that underwater construction is difficult? Mankate underwater epoxy resin adhesive to help!

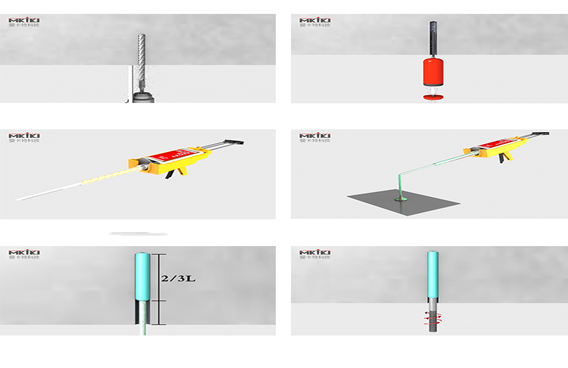

Nanjing Mankate underwater epoxy reinforced adhesive MT500-W, before the planting of the ribs to ensure that the water is static. It can not flow water to the hole. The process of other planting ribs and ordinary epoxy planting glue is no difference. The construction of underwater epoxy resin reinforced adhesive is also divided into six steps.

Underwater epoxy resin reinforcement is also divided into six steps! Mankate Epoxy Reinforced Adhesive is escorting the project!

(1) Punching: Before the construction of epoxy resin mortar, it is necessary to drill according to the design drawings of the project.

(2) Clearing holes: The holes must be cleaned, and the construction of the ribs can be carried out without any extra impurities in the holes.

(3) Injection: In addition to the above mentioned need to soak before the epoxy resin injection hole, we should also pay attention to the normal injection amount of 2/3 of the pore volume.

(4) Planting bar: After filling the glue, the rebar or ribbed bar will be slowly rotated clockwise and inserted into the bottom of the hole. The surface of the steel part of the implanted part must be rusted and the surface of the steel bar is free of excess oil. The position of the reinforcing bars is also required to be adjusted by means of a tool during the rotation into the hole.

(5) Inspection: After the steel bar is solidified, a pull-out test shall be carried out on the embedded steel bar. The purpose is to check whether the quality of the epoxy reinforced adhesive is passed, and whether the construction details are well controlled.

(6) Maintenance: After the planting is completed, it is necessary to ensure the quality of maintenance and curing time.

Mankate's epoxy reinforced adhesive has been broadcasted by CCTV, and the quality is reliable!

Mankate Epoxy Resin Reinforced Adhesive has been broadcasted by CCTV. It is also rated as China's famous products, and the quality is reliable. If you have the need for reinforcement of epoxy resin reinforced adhesive, please call Mankate Epoxy Reinforced Adhesive. One-stop service hotline: 400-894-5118, we will provide you with professional answers for 24 hours a day.

Link to this article: https://www.njmkt.net/Article/sxzjjdsyff.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)