● Material: alloy steel grade 5.8, 6.8, 8.8, 10.9, 12.9; stainless steel 50 70 80

● Designed high strength chemical anchor, suitable for all kinds of concrete base material, even cracked concrete

● The main components of the chemical cartridge are modified epoxy resin, grade A adhesive; high/low temperature resistance and aging-resistance

● We also provide specialized underwater adhesive for damp and water-filled holes for effective anchorage

● We recommend our excellent NJMKT Anchorage Adhesive (MT-500 cartridge or barrel) for NJMKT adhesive anchors

Characteristics

● Fast cure, small spacing and edge distance, quick construction efficiency, good weldability

● Excellent comprehensive performance, safe and reliable, construction tolerance is higher than conventional chemical anchor, non-toxic environmental protection, aging-resistance up to 50 years and high/low temperature resistance

● Comparing with mechanical anchors, the same tensile strength characteristics but low price advantage for your choice

● steel structure

● bridge and tunnel

● industrial plant

● building curtain wall

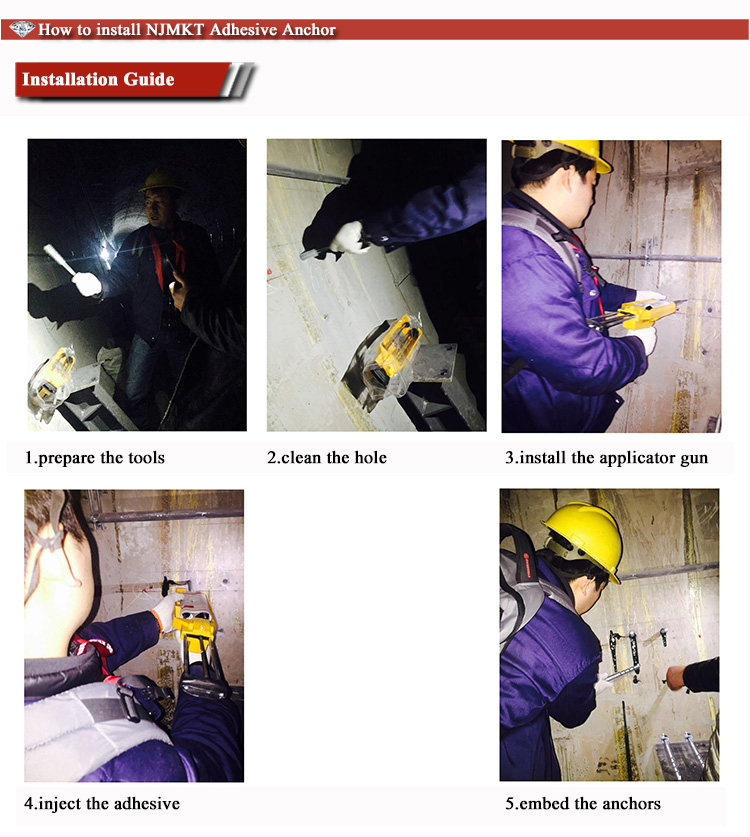

Installation Guide

| Cure Schedule | |||

| Base material temperature [°C] | Installation time [minute] | Gel time [minute] | Cure time [day] |

| -5°C ~ 0°C | 40 | 90 - 150 | 8 |

| 0°C ~ 10°C | 25 | 50 - 90 | 6 |

| 10°C ~ 25°C | 15 | 35 - 50 | 4 |

| 25°C ~ 40°C | 6 | 15 - 35 | 2 |

| ≥ 40°C | 4 | 7 | 1 |

● Drill the hole to proper depth and diameter per specifications using drill systems.

● Clean the hole using brush and compressed air.

● Use specialized cartridge, place the cartridge into the dispensing tool, discard the first several times of injection until an even-colored mixture is extruded.

● Insert the mixing nozzle to the bottom of the hole, and inject adhesive until the hole is about 2/3 full.

● Embed the steel anchor element to the bottom of drilled hole clockwise slowly.

● Check the surface of the hole if there is any overflow to ensure the hole is full. There shall be no gaps between the anchor and the wall of the drilled hole. Clean any excess resin from around the mouth of the hole.

● Do not knock or strike the steel during cure time.

● Finish installation and continue the follow-up construction.

Adhesive consumption reference

| Anchor rod | Drilled hole diameter mm | Drilled hole depth mm | One cartridge available for hole numbers |

| M8 | 10 | 80 | 100 |

| M10 | 12 | 90 | 62 |

| M12 | 14 | 110 | 37 |

| M16 | 18 | 125 | 20 |

| M20 | 24 | 170 | 8 |

| M24 | 28 | 210 | 5 |

| M30 | 35 | 280 | 2.4 |