The bridge has been used for a long time, and it is also inspected every year to ensure the quality and safety of the traffic. The purpose of the bridge inspection is to find out the defects and hazards through the technical conditions, defects and the nature, location, severity and development trend of the bridge. The main factor is to provide reliable technical data and basis for the bridge repair and reinforcement program. General bridge testing uses static load experiments, so what is static load test?

The static load test of the bridge is to check the vertical deflection, lateral deflection and variation of the bridge. In addition, at least three checkpoints should be inspected at least in the bridge structure and the maximum deflection, deformation and relative settlement values of the bracket are determined according to the specifications. In other cases, the calculation theory selected during the test can verify the internal force of the bridge control section through long-term observation, and can also calculate and test the longitudinal and lateral influence lines of the deflection.

How to strengthen the bridge that detects the problem? It is recommended to use Mankate carbon fiber cloth for reinforcement:

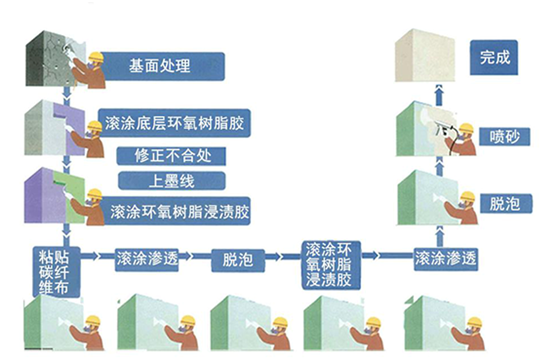

1. The base surface is treated first, and it is completely polished without any attachments. Then roll the carbon fiber primer, scrape the leveling glue, and correct the mismatch, the ink line.

2. Then roll the carbon fiber impregnated adhesive onto the bonding surface, and the amount of glue must be sufficient and full. Then put the cut carbon fiber cloth on the concrete coating surface, and the carbon fiber cloth should be straight and extended.

3. Roll the carbon fiber impregnated adhesive

on the carbon fiber cloth to ensure that the surface of the carbon fiber cloth is fully covered to ensure sufficient wetting of the fibers in the carbon fiber cloth. The squeegee is repeatedly pressed to promote the carbon fiber cloth to be straight, extended, and free of bubbles, and the carbon fiber glue is fully penetrated.

4. Roll the carbon fiber impregnated adhesive again to make it infiltrate, and repeatedly scrape and defoam using a scraper. Finally, spray 3-6 mm sand (quartz sand) on the coated surface to ensure the adhesion of the paint layer.

In the reinforcement of bridges, the selection of materials is critical. Nanjing Mankate carbon fiber cloth is made of imported carbon wire, which has high flatness and no discrepancies. When the carbon fiber glue is used to firmly hold the carbon fiber cloth and the concrete structure together, a special stress is generated, which increases the toughness of the bridge, and it can slow down the crack generation and greatly improve the building life. Mankate carbon fiber cloth reinforcement system, 50 years warranty, hotline: 400-894-5118

Link to this article: https://www.njmkt.net/

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)