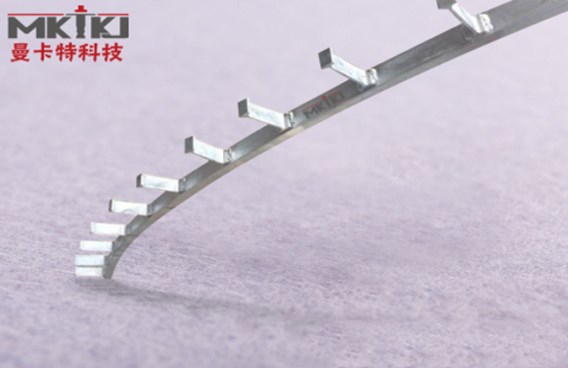

In recent years, the State has successively issued the "Guiding Opinions on Strengthening the Management of Urban Underground Pipelines" ( [2014] No. 27) and the "Notice on Launching the Pilot Work of the Central Financial Support Underground Pipe Gallery" ([ 2014] No. 839), issued a series of documents from the policy, finance and other aspects, and vigorously promote the construction of integrated pipe corridors. It is not difficult to see the emphasis of the state. Today, we will invite experts from Mankate Technology to analyze the technical points of concrete pouring, maintenance and demoulding of the arc-shaped pre-buried channel of the pipe gallery.

The concrete pouring, maintenance and demoulding of the arc-shaped pre-buried channel of the pipe gallery is based on the completion of pipeline positioning and is a supplement to the positioning. In order to ensure the quality of positioning, concrete should be poured in time. In addition to ensuring the quality of concrete raw materials, the quality of the pouring process should be strengthened. Therefore, it is necessary to strictly follow the technical points of the pre-buried construction of the contact network pipeline, and effectively strengthen the concrete pouring work. Generally, the pouring is carried out in a layered manner, and at the same time as the pouring, the vibrating work should be strengthened to achieve one-side pouring. While vibrating, it should be fast-plugged and pulled slowly to ensure the quality of vibrating as much as possible.

On the basis of simultaneous pouring, it is also necessary to strengthen its maintenance and release treatment in a timely manner. By strengthening its maintenance, it is necessary to timely demolish the mold after ensuring that the maintenance cycle is reached. In the process of demoulding, the bolt should be reversely rotated after the bolt is loosened, and the plugging piece is opened while the bolt is taken out. If there is cement slurry on the surface of the pipeline, it should be strengthened in time. And after the film is removed, the pipeline is inspected comprehensively and carefully, so that the construction quality is controlled to prevent quality problems. Therefore, it is also necessary to strengthen the handling of its engineering quality problems in a timely manner, and to ensure the pre-buried quality of the arc-shaped pre-buried channels of the pipe corridor.

This is the summary of the main points of concrete pouring, curing and demoulding techniques for the arc-shaped pre-buried channel of the pipe gallery. If you are interested in this product, please call our one-stop service hotline: 400-894-5118.

Link to this article: https://www.njmkt.net/Article/glymcdhntj.html

(Editor: Nanjing Mankate, if you need to reprint, please indicate the source)