Features:

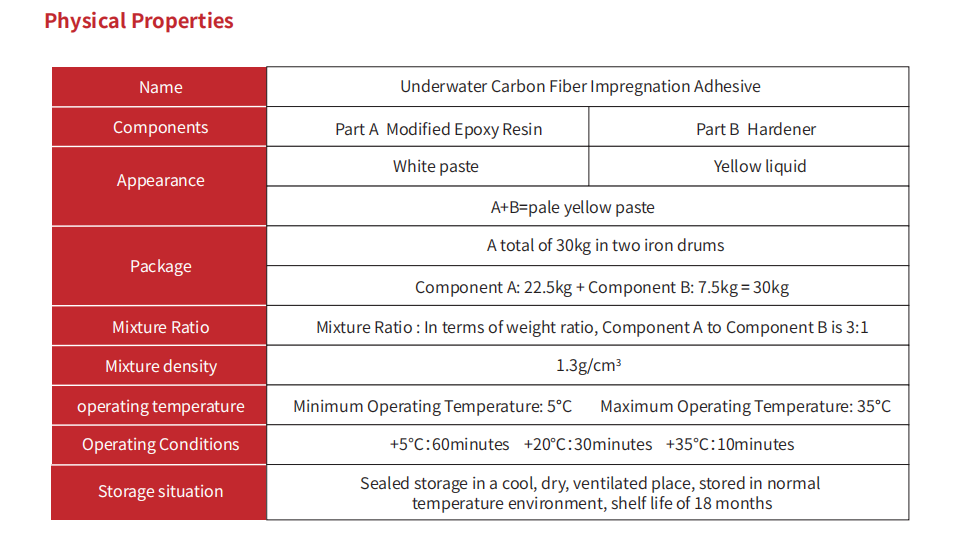

● Main components: modified epoxy resin, nanomaterials, other additives

● Component A: Component B = 3:1, two-component anchoring adhesive, fast-cure, epoxy-based anchoring adhesive, nearly odorless, non-toxic, permenent thixotropy.

● Quick load-bearing after cure, high initial bonding strength, good toughness and anti-pulling capacity

● Low density, excellent thixotropy, smooth, no sediment

● Good resistance to high temperature, age, chemical corrosion, welding, seismic, flame, etc.

● Almost no shrinkage during curing process

● When properly mixed, adhesive will reveal an even color

● Mixed adhesive should be used up within 10~30 minutes (depending on specific ambient temperature)

● The density is about 1.65~1.70 g/cm3 (cured ), gel time is about 1.5~6 hours

● Barrel package is suitable for applicator gun to inject adhesive

Operating environment:

Underwater condition

Package:

Packing: 30/10kg barrel

Storage:

Shelf life: At least 12 months from date of manufacture in unopened container when store in dry and well-ventilated place. Please store in ambient temperature from 5 ℃ to 40 ℃, away from open flame, heating devices

Handle with care, protect from rain, sunlight and place upward during loading and unloading transportation

If the temperature is low, component A and B can be separately warmed in 40 ℃ warm pot (barrel) to decrease the viscosity

The construction environment temperature is better for below 40 ℃, at normal temperature gel time is 2 hours, initial cure time is 24 hours, at negative temperature or wet condition, cure time will be a little longer.

Caution

Mix the adhesive well according to its weight proportion strictly

Construction crew should take steps of protective measures to keep it from eyes

Remaining adhesive cannot be poured into original barrels

Note:

1. d is the diameter of rebar

2. When the density of rebar is high, the embedment depth should be increased appropriately

3. When added new components are other structure components, the concrete strength with original components should not be less than C20

4. When added new components are cantilever structure components, the concrete strength with original components should not be less than C25

Rebar Diameter & Corresponding Design Value of Drilled Hole Diameter

| Rebar diameter d (mm) | Design value of drilled hole diameter D (mm) |

| 12 | 15 |

| 14 | 18 |

| 16 | 20 |

| 18 | 22 |

| 20 | 25 |

| 22 | 28 |

| 25 | 31 |

| 28 | 35 |

| 32 | 40 |